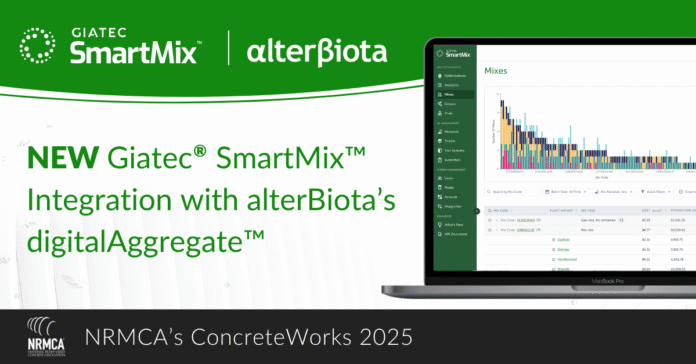

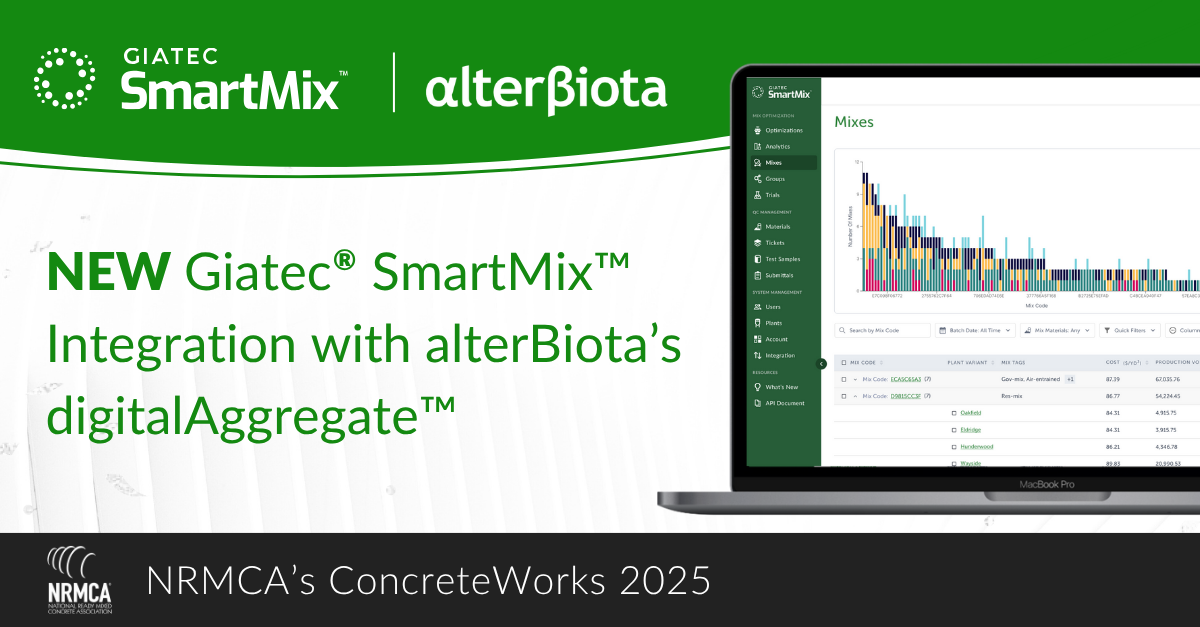

The integration with alterBiota’s digitalAggregate™ technology brings real-time aggregate data to Giatec’s AI-powered SmartMix™, advancing precision and performance in real-time concrete mix optimization.

OTTAWA, ON / ACCESS Newswire / October 9, 2025 / Giatec®, global leader in concrete technology platforms, announces the launch of a seamless integration with concrete technologies innovator, alterBiota. The collaboration integrates alterBiota’s digitalAggregate™ technology with Giatec’s AI-powered SmartMix™ platform, bringing real-time aggregate data directly to SmartMix to expand optimization opportunities and deliver an end-to-end quality control solution for ready-mix producers.

SmartMix™ integration advances concrete mix optimization.

BARD Materials, a North American ready-mix producer, was among the first customers to pilot this integration. “Integrating alterBiota’s digitalAggregate with Giatec’s SmartMix platform solves the critical challenge of gradation in concrete optimization,” said Tony Thier, President of BARD Materials. “This breakthrough enables a true shift to performance-based designs and predictive quality control. Giatec’s predictive, AI-driven models will advance the industry beyond traditional charts into an era of smarter, leaner concrete manufacturing.”

Aggregates make up roughly 3/4 of a concrete mix, yet most producers rely on infrequent and time-consuming sieve analyses that provide limited insights for day-to-day operations. digitalAggregate™ transforms this process using advanced computer vision to analyze images of aggregates captured with any smartphone to provide actionable, real-time data. This enables more frequent testing and the ability to respond to variability in real-time, ultimately building a richer perspective on historical material performance and quality. Through this integration, real-time gradation data is uploaded to SmartMix and Roxi™, Giatec’s AI engine, promptly checks if workability or performance optimizations are available, optimizing cement use and offering new opportunities for reducing embodied carbon.

“With just a smartphone, BARD Material’s team can now capture size, shape, and texture data on aggregates in real time, enabling rapid, high-frequency results with minimal effort,” said Mark Masotti, CEO of alterBiota. “Integrating digitalAggregate with Giatec’s SmartMix platform marks a step change for advanced quality control and mix optimization in concrete production.”

“This is only the first step in a much larger partnership. In the near term, producers can expect empowered data-driven QC decision making, advanced optimization opportunities, and better control over material inputs,” said Aali Alizadeh, CTO and Co-founder of Giatec. “Long term, the vision is even bigger: fully connected quarries, batch plants, and job sites sharing data to fine-tune concrete quality from the source. Our collaboration with alterBiota reflects Giatec’s vision for a future where intelligent integration and innovation drive efficiency and quality across concrete production.”

Giatec and alterBiota invite ready-mix producers attending NRMCA ConcreteWorks to see first-hand how digitalAggregate, AI-powered mix optimization, and in-transit monitoring work together to deliver concrete of the highest quality. Along with this new integration, the entire Giatec ecosystem, including MixPilot™ and SmartRock®, will also be on showcase at booth #215, in Orlando, Florida, from October 10 -12, 2025. Attendees visiting will see live demonstrations and learn how AI-driven adjustments can cut carbon emissions by up to 20%.

Contact Information

Dobrila Moogk

Senior Vice President, Marketing, Giatec Scientific

marketing@giatec.ca

+1 (877) 497-6278 ext. 9210

SOURCE: Giatec Scientific Inc.

View the original press release on ACCESS Newswire